ERP vs SCM: Which one is better?

Source: https://www.eritrium.com/en/crm-erp-scm.html

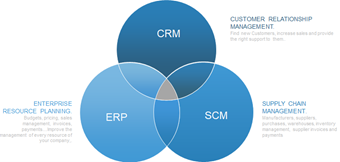

There are few questions regarding SCM and ERP, which one is better? What are the differences? What should businesses implement first? Those questions will be answered in this article. To find out the differences between the two, we must first know the description of each of the enterprise applications. Starting from ERP, ERP is an integrated system and software package that are used by companies/ organizations to manage their daily business activities, such as financial management, production, projects, procurement, Human resources, and many more. Inside that single software, many modules can be installed depending on the vendor which will be useful for data transfer. Many say that ERP is the backbone of the business process because it integrates the departments in the company and provides many advantages for the company.

SCM is the abbreviation for Supply Chain Management, it is a series of activities that consist of managing, coordinating, scheduling, controlling the production, procurement, inventory, delivery of products or services to customers which includes daily administration, logistics, operations, and information processing from customers to suppliers. SCM will be very useful for companies that make or provide their services/ products such as manufacturers, service companies, etc. To be competitive, a company must understand their supply chain and develop a strategy which can improve their supply chain management.

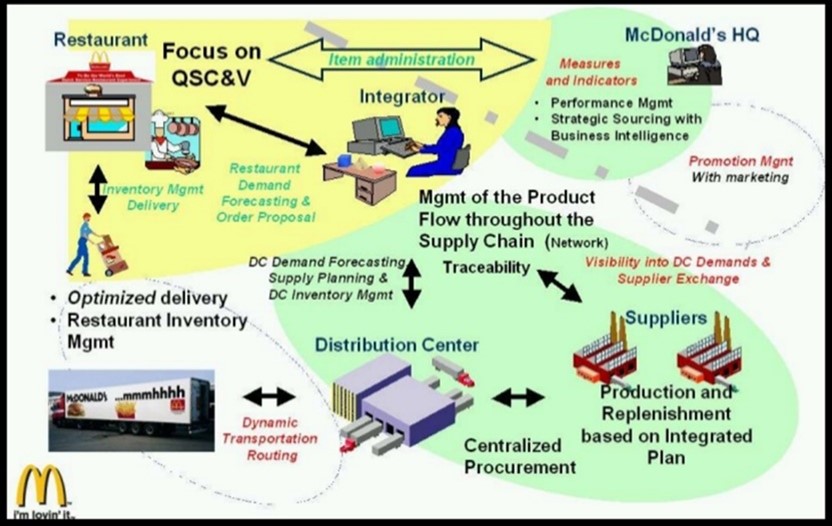

Source: https://medium.com/@jainaditya017/supply-chain-management-of-mcdonalds-india-58e1064274b5

Let’s take McDonald’s as an example for a big company that has become successful because of good supply chain management. Due to the exchange of values and success, McDonald’s and its suppliers have a very bond relationship that forms an excellent supply chain. This approach has proven to be successful. Now, McDonald’s is the world’s largest restaurant chain that has branches spread over 100 countries across 37,885 outlets serving over 69 million people daily. McDonald’s supply chain is a complex web of direct and indirect suppliers with standards that must be met to maintain quality and efficiency. Direct suppliers are used to coordinating purchasing and distributing to restaurants. While, indirect suppliers are used to operating facilities (ex: grain mills, abattoirs).

There are significant differences between ERP and SCM which are:

- ERP: Has a lot of functionalities (various modules).

SCM: Limited functionalities and covers only supply chain functionality.

- ERP: Has a high complexity because it integrates various departments.

SCM: Not as complex as ERP.

- ERP: Its sourcing tables are relatively static.

SCM: Its sourcing tables are relatively dynamic.

- ERP: All the constraints including demand, capacity, and material constraints are considered separate from each other.

SCM: Handling the constraints simultaneously.

- ERP: Its functionality is less dynamic because it focuses on the speed and capacity of the transaction process.

SCM: Its functionality is more dynamic because it simulates transaction adjustments by paying attention to constraints in real-time.

- ERP: The speed of processing is relatively slower.

SCM: The speed of processing is relatively faster.

Although, from the differences above we can see there is a business application that seems to have more benefits for the company. But when we talk about which one is better, it depends on the company’s needs. A company can implement ERP or SCM only or even integrates both SCM and ERP simultaneously. For example companies like manufacturers probably need SCM to support their business process, but banks don’t need SCM. Banks don’t need it because they don’t have suppliers, they can just implement ERP. Hence, whether a business should implement SCM or ERP depends on the company’s needs and their business type.

As for which business application that company should implement first again depends on the company’s needs. A company can implement ERP first and then SCM, or they want to implement SCM before ERP is also fine. There are several possible reasons why companies implement SCM first: insufficient budget, there are no competent human resources in ERP, type of business that produces its own goods/ services (manufacturers), etc. But companies also can implement ERP before SCM as it is the backbone of the business process. ERP integrates data from various departments and functions throughout the organization into an integrated software that improves the effectiveness of data flow. It also improves decision-making and increases data transparency. ERP vendors such as Epicor, Oracle, SAP Business One also come with a built-in supply chain module, so there’s no need for a stand-alone SCM. To sum up, no business application is better or worse, it all depends on the company’s needs.

References link: